CONATECwww.conatec.com

CONATEC

C\ Gabiria nº 112-114-146

Pº Ventas 20305

Irún (Guipúzcoa) SPAIN

Tel.: +34 943 633 562

Fax: +34 943 633 285

E-Mail: conatec@conatec.com

C\ Gabiria nº 112-114-146

Pº Ventas 20305

Irún (Guipúzcoa) SPAIN

Tel.: +34 943 633 562

Fax: +34 943 633 285

E-Mail: conatec@conatec.com

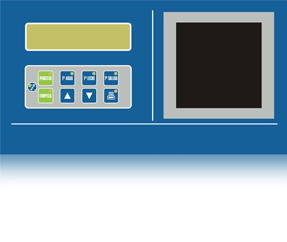

Control for pasteurization machines

The control for pasteurization processes allows for all the operations necessary for the pasteurization of dairy and similar products, being able to carry out a totally automatic or manual pasteurization process.

It is valid to work with different types of machines in accordance with the configuration stipulated by the manufacturer.

General Characteristics

- Power: 220VAC.+/-20% (50-60Hz.).

- Electrical consumption: 4VA.

- 2x16 alphanumeric character LCD display of 10mm.

- 4 LED green pilot lights to indicate the state of the control.

- 4 LED amber pilot lights to indicate process or cleaning operation.

- 1 LED red pilot light to indicate a warning.

- Three PT100 type inputs to control the temperature of water, milk and output.

- Protection against the breakage of the PT100 sensor incorporated.

- Error indication less or equal to +/- 0.2 units +/-0.2 % of the measurement indicated.

- 2 logic inputs of 220VAC. for thermal inputs of pump and resistors. An input for a 2 wire passive collector for a pressure or flow collector (selectable by configuration) of 4/20mA to indicate the retention time of the milk circuit.

An input for a pulse flow meter with a Namur output to indicate the time of retention of the milk circuit.

- Two inputs to read the level. One to read the level by buoy or PTC in the primary circuit and another to capture

the level by electrode in the secondary circuit or in the supply tank, according to configuration. - 3 SPST type relays of 5A to 220VAC for resistive load, free of power with a common conductor, for the operation of: water temperature (increase in case of servo), water temperature (lower in case of servo), and diverter valve.

- 8 SPST type relays of 5A to 220VAC for resistive load, free of power with a common conductor for the operation of different valves for the automatic operation of the Pasteurization process. Selector in milliampere mode.

- One 4/20mA signal output for the output with servovalve.

- 1023 parts resolution.

- Acceptable maximum load of 150.

- This output is prepared to work with resistor systems. If it is connected to systems with great capacity or inductance, anomalies in operation can occur.

Environments

- Environmental operating temperature between 0 and 50ºC.

- Relative humidity of operation between 0 and 80% without condensation.

CE Mark

- Three temperature regulators/indicators are integrated in the control with the following functions:

- 1. A temperature regulator for the primary water circuit of the exchanger which can be configured to operate in:

- A) A closed circuit which acts on the water heating resistors to achieve the programmed water temperature in the exchanger.

- B) A closed circuit with water which comes from an industrial heater which acts on a servomotor which diverts part of the water flow to achieve the programmed water temperature in the exchanger.

- 2. A pasteurization temperature regulator which acts on a recirculation diverter valve.

- 3. An output temperature regulator which acts on a servomotor which diverts part of the flow of the cooling water to achieve the desired water temperature. in the case where this regulator is not used, the equipment will only indicate and inform of the exit

- 4. It has a real time watch which will remain on time even if the power to the equipment is disconnected and will serve to print the reports with the time and date of the pasteurization result.

- 5. It has a rs232 communication to connect to either a printer or a computer to dump the pasteurization report data. in the case where it is connected to a computer, it can be controlled from that computer. for example to change instructions, start up, stop, etc.

- 6. It has a level logic input to electrodes or ptc to detect if the primary water circuit is not level and prevent break downs in case of overheating by electrical resistors when there is an insufficient level of water.

- 7. It has an input from a flow meter with a namur sensor to measure the flow and regulate it, acting on the regulator valve to control the retention time of the secondary milk circuit. to configure it, the input and the retention time control can be cancelled.

- 8. It has a 4/20 ma input for the same function as above.it can also be configured as a measurer and regulator of the milk circuit pressure. this input can be cancelled by configuration.

- 9. It has two 230 vac inputs. which come from the thermal circuit breakers of the milk pump and the thermal circuit breakers located in the resistors to detect break downs.

- 10. It has a buzzer and a relay to remotely activate a breakdown warning, in addition to a indicator light of anomalies in the system, in the case of signal anomalies, breakage of temperature probes, break downs in the printer or the thermal circuit breakers, etc... when an anomaly is detected it is also shown on the equipment display.

- 11. It has a button with a light to select the printing operations of the pasteurization report.

- 12. It has relay outputs to act on the valves for a totally automatic cleaning operation and the diversion of the milk. in the case of not using the outputs because a manual operation is desired, these outputs will not be operative and can be deactivated through the configuration.

- 13. It has three 2 wire pt100 inputs to control the temperature of the primary water circuit, the temperature of the secondary milk circuit and the temperature of the output cooling circuit. an optional printer can also be supplied.

Attached archives:

-

Control for pasteurization machines

[607Kbs.]

Control for pasteurization machines

[607Kbs.]

We use our own and third party cookies, for the analysis of user navigation. If you continue browsing, we consider that you accept the use.

You can change the settings or get more information here.